Advancing Industrial Hardware with Aluminum Forging #

Al Forge Tech Co., Ltd. (AFT) specializes in the forging and precision machining of aluminum alloy parts, delivering high-strength, lightweight, and customizable solutions for a wide range of industrial hardware applications. Our expertise and rigorous process control ensure that each component meets the demanding requirements of modern industries.

Core Process: Aluminum Alloy Forging #

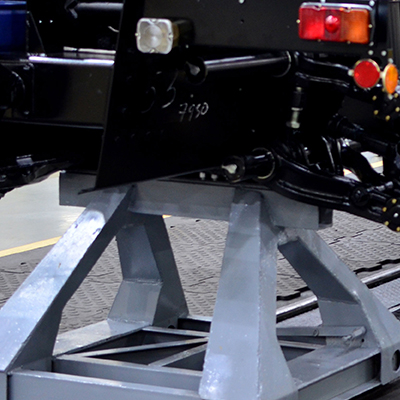

Our aluminum alloy forging process is at the heart of our industrial hardware solutions. Through years of technical expertise and strict process management, we produce forged parts that are widely used in the following sectors:

Machinery manufacturing

Machinery manufacturing

Electronic assembly

Electronic assembly

Medical equipment frames

Medical equipment frames

Sporting equipment components

Sporting equipment components

Logistics and handling systems

Logistics and handling systems

Industrial door control and locks

Industrial door control and locks

Military machinery structural supports

Military machinery structural supports

Aluminum Alloy Materials: Balancing Lightness and Performance #

Forged aluminum alloy parts are increasingly replacing traditional steel and cast components in industrial applications. The key advantages of AFT’s aluminum alloys include:

- Lightweight (about 1/3 the density of steel), reducing structural weight and improving efficiency

- Excellent corrosion resistance, suitable for outdoor and humid environments

- High thermal and electrical conductivity, ideal for heat sinks and electronic assemblies

- Anodizable and surface treatable for enhanced aesthetics and protection

- High toughness and ductility, capable of absorbing impact and fatigue

We select optimal alloy grades such as 6061T6, 7075, and A356 based on customer requirements, and provide comprehensive material certifications and testing reports.

Application Categories #

AFT’s aluminum industrial hardware parts are available in a variety of categories to suit diverse industrial needs:

- Handles & Knobs

- Hinges & Latches

- Slides & Brackets

- Mounts & Feet

- Structural Joints

- Industrial Pulleys & Shafts

Commitment to Quality Assurance #

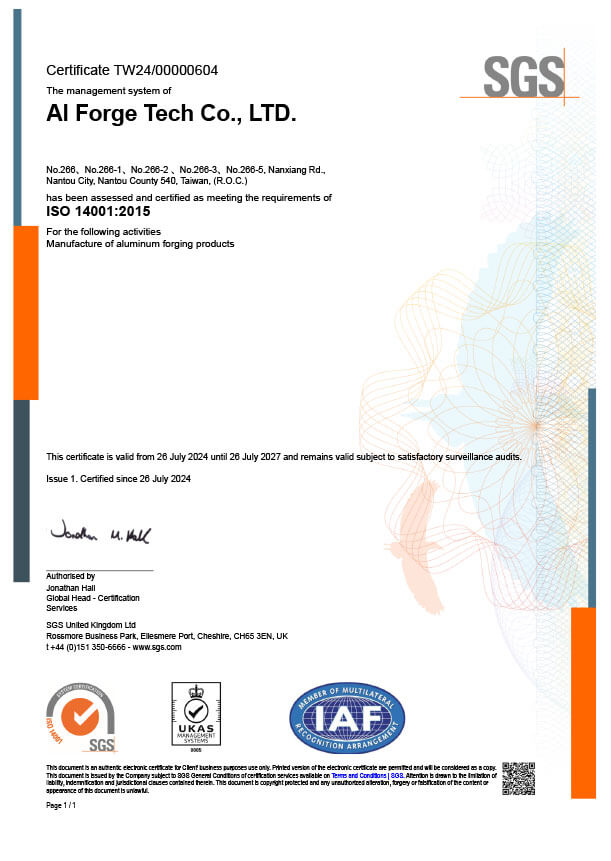

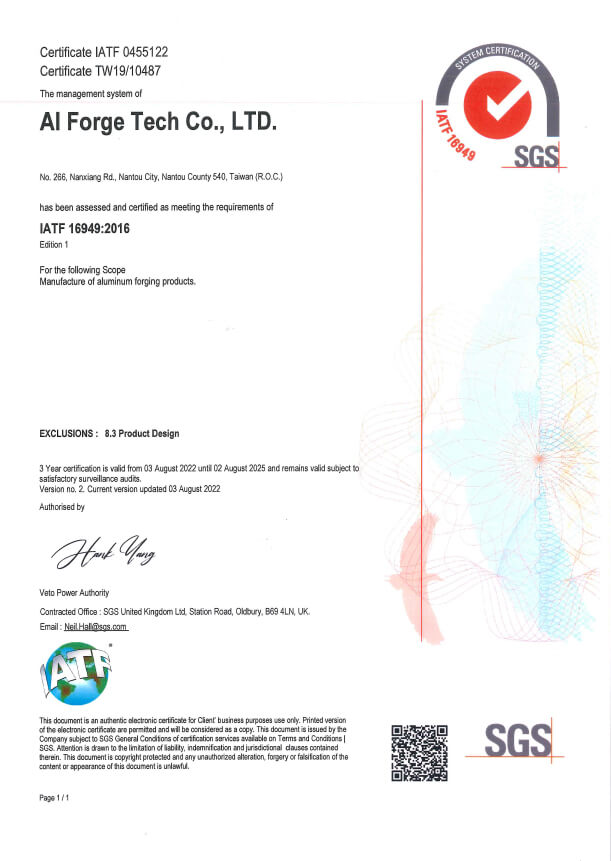

Our production processes adhere to international standards, including ISO 14001 Environmental Management and IATF 16949 Automotive Quality Management. From material selection through forging, machining, inspection, and delivery, every stage is meticulously controlled.

- Full dimensional inspection using Zeiss CMM

- Surface roughness and hardness testing

- Complete inspection reports and material certificates for each batch

ESG Practice: Sustainable Manufacturing in Action #

AFT is dedicated to sustainable manufacturing, integrating environmental, social, and governance (ESG) principles into our operations.

Environmental Initiatives #

- Increasing the use of recycled aluminum annually

- Sorting and reusing forging and machining waste

- Implementing water recycling in anodizing and surface treatment

- Planning solar system installation to reduce carbon footprint

Social Responsibility #

- Regular employee health and safety education

- Local sourcing to support regional supply chains

- Supporting academia-industry collaboration and training

Governance #

- Internal ESG governance committee

- Data management and reporting aligned with international standards

- Regular audits of ethical and compliant production

Choose AFT for reliability, safety, and a commitment to a sustainable future.

For more information or to discuss your specific requirements, contact us.

Aluminum Industrial Hardware Parts

Aluminum Industrial Hardware Parts 工業五金-1

工業五金-1